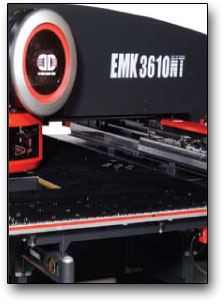

We are writing to express how pleased we are with your EMK3610NT Amada turret machine. The increased productivity we have seen and the overall capabilities of your machine are truly impressive, and we commend you on your excellent product.

The features we have found to be truly impressive are the exceptional speed of the machine and the ram hold-down option. The EMK3610NT is exceptionally fast and the ram hold-down option has allowed us to do miles of wheel forming operations with the auto index station. We are able to machine larger sheets of metal in a timelier, more efficient manner, increasing our overall productivity.

Another feature that has been very impressive is the roll forming emboss feature. This has allowed us to create designs without the additional use of a stamping system, has provided us with the flexibility to change aesthetic designs for our models, and has helped set us apart from our competitors.

In addition to the machine’s impressive features, the machine is impressively quiet, emitting hardly any noise, which has helped decrease the overall noise volume of the shop and is an additional benefit.

Lastly, in over two years of use, the EMK3610NT has had zero down- time with no replacements, adjustments, or problems. This is a testimony to the quality of your product and is another reason why we have purchased additional Amada products. We sincerely appreciate your product and commend you on producing such a reliable and efficient machine.

Stan Visness

Engineer Central Boiler Inc.

Greenbush, MN

|

|

|

Spend more time punching: Amada’s triple track turret is available in a variety of configurations with up to 58 stations up to 4 ½" diameter, and up to four (4) auto-index stations. This allows you to use a wide range of tools without being forced to use expensive, hard to maintain, set-up and program multi-tools.

|

|

|

It’s been almost one year since the installation of our fourth EM2510NT Turret Punch Press w/MP1225 Material Handling System. I would like to say that it’s been working out great. By providing us with enhanced workload efficiency, we are able to significantly increase our production capabilities.

It feels good to know that that we can rely on these machines to help meet the needs of our customers by aiding in the production of high quality products.

Thank you for helping us achieve a simpler, more cost-effective means of manufacturing.

Son Ho

President

All FAB Precision Sheetmetal, Inc.

|

|

|

I feel the decision to purchase the Amada EMK3610NT was one of the best decisions Merritt Equipment Co. has ever made. Some of the pluses of the EM machine that we have recognized are:

- Low energy consumption

- Very low maintenance costs

- No hydraulic pump or chiller to maintain

- Remarkable accuracy and repeatability

- Ease of navigation from one program to another

- Ability to keep track of tool usage

- Ease of prodedure for setting tooling parameters

- The machine displays daily maintenance messages

- The speed of the EM is unbelievable

- The smoothness while operating

- Very low noise level while machine is operating

- No hydraulic pump or chiller noise because they have been eliminated

- The operation of the sensors which help prevent machine damage (because of a bad program or bad material) is excellent

- Ease of keeping machine clean

- The compatibility of programs and tooling between the EM and the 368 King is a big plus

If you have any questions please feel free to call me at 303-289-2286 ext.170. Tim Steinbach Production Manager Merritt Equipment Co.

|

|

|

Fact: Amada servo drive systems contain hundreds fewer parts than hydraulic machines. That means no pumps, valves, seals, or hydraulic lines to leak or fail, and no chiller to help make your shop even hotter during the summer!

(EM-series twin drive shown)

|

|

|

Our application of the Amada EM2510NT has resulted in impressive cost benefits through cycle time improvements, as well as the elimination of secondary operations. Amada offers a full complement of knowledgeable, conveniently located Sales and Service professionals who are always willing to answer any questions we may have. The seamless transition of the EM2510NT into our business serves as testament to the skill and availability of this team. I would highly recommend the EM2510NT, as I am very pleased with our experience.

Christopher C. Koontz

Manufacturing Engineer

B/E Aerospace

|

|

When we first saw the EM2510NT Turret Punch Press we were impressed with its sleek styling, quiet operation and lightning fast speed. The state-of-the-art PC-based control is easy to use and makes setups and tooling changes extremely quick. Compared to our existing machine the larger table size increased our yield rates while reducing scrap. Run times are two to three times faster, which allows us to be more competitive in today’s market and offer faster turn around times – which are key to customer satisfaction. The accuracy and repeatability in positioning, forming and countersinking have improved our ability to supply the highest quality product to our customers. The EM2510NT turned out to be a perfect addition to our precision fabrication facility and exhibits the performance and reliability that we’ve come to expect from Amada equipment.

Barry Yoder

Sheet Metal Shop Manager

Myers Sheetmetal Division of Kampel Enterprises, Inc.

|

|

Here at D & B Precision Products, Inc., our family-owned business has been experiencing many changes and much growth. For many years, however, the machines that we have used have been sufficient in producing parts and meeting customer demands. However, with our recent business growth, we determined that it was time to make a big decision, which to us, equated to a very large purchase. We were concerned about taking enough time to consider all of our options and we wanted to be certain in our choices and confident in our final decision.

The process from the beginning to the end, and even up to today, has been seamless. After carefully considering several options, we made our choice to purchase the Amada EM2510NT. We also strongly considered buying a competitor’s machine, but after being presented with the specific differences between the machines, we realized the Amada EM2510NT would best fit our company needs and desires.

Our appreciation, recognition and thanks go to Alden Hunt and the professional staff at Amada America, Inc. for all of their support!

Dave & Brenda Alberti

President & Vice-President

D & B Precision Products, Inc.

|

|

|

Are you concerned about your environmental responsibility and interested in saving a lot of money? Amada servo drive turrets consume approximately one-half the electricity of hydraulic machines. That can easily amount to savings of thousands of dollars every year.

|

|

|

We have been very pleased with the EMK3610NT / MP1530 Amada punching cell. We have seen several benefits after upgrading from the Vipros 255/MP1225. The larger table gives us the ability to increase blank sizes, and the larger turret capacity helps us generate more dynamic nests. As a result, in some applications we have reduced our scrap by up to 25%. This is invaluable with today’s surge in raw material costs.

The faster speed of the EMK3610NT has allowed us to run jobs during the day that were that were once run overnight, and increase our capacity by nearly 60%. It has been a nice capacity gain without adding additional people or a second shift.

The reliability has been great; the cell will typically run over 16 hours a day and some weekends. The MP allows us to runs lights-out, which accounts for about 50% of the total machine run time. It hasn’t missed a beat. There have been no major issues or downtime and the guys don’t miss changing the water and oil at all.

Dan Lewis

President

Fabrico Inc.

|

|

|

Fact: Amada turrets are the heaviest-duty in the industry. Compare the construction and weights to any other machine. The payoff to you is in higher accuracy, better quality parts, and longer tooling life, year after year.

|

|

- Speed

- Reliability

- Increased Productivity

- Low Operating Costs

- Easy-To-Use, Full-Featured Controls

- Reduced Maintenance

- Increased Material Utilization

- Reduced Labor Costs

- Faster, Easier Setups

- Low Noise Operation

- “Lights Out” Running Capability Using

- Flexible Automation

- Amada Team Support

|

At Amada, we realize that new equipment purchasing decisions are more important now to the growth (and sometimes the very survival) of your business than ever before. That’s why we’ve made the investment in developing new technologies such as servo drives when most other manufacturers have continued to “make do” with old-fashioned hydraulics. We are not the only manufacturers of CNC punching machines, but we feel that upon a detailed and open-minded examination you will agree that Amada machines are clearly superior to any other. Let us prove it to you by providing a detailed analysis of your current and future punching needs.

|

|