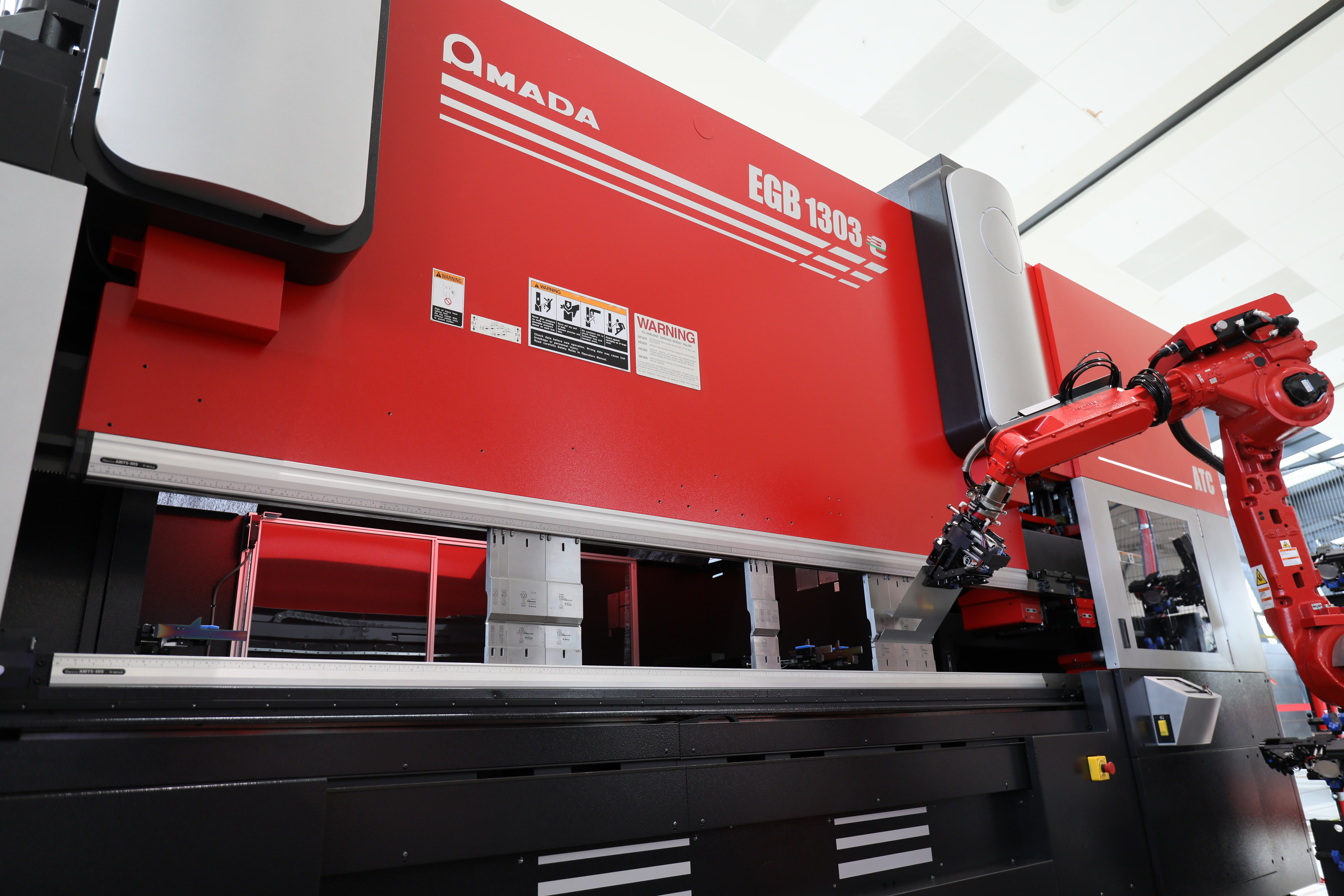

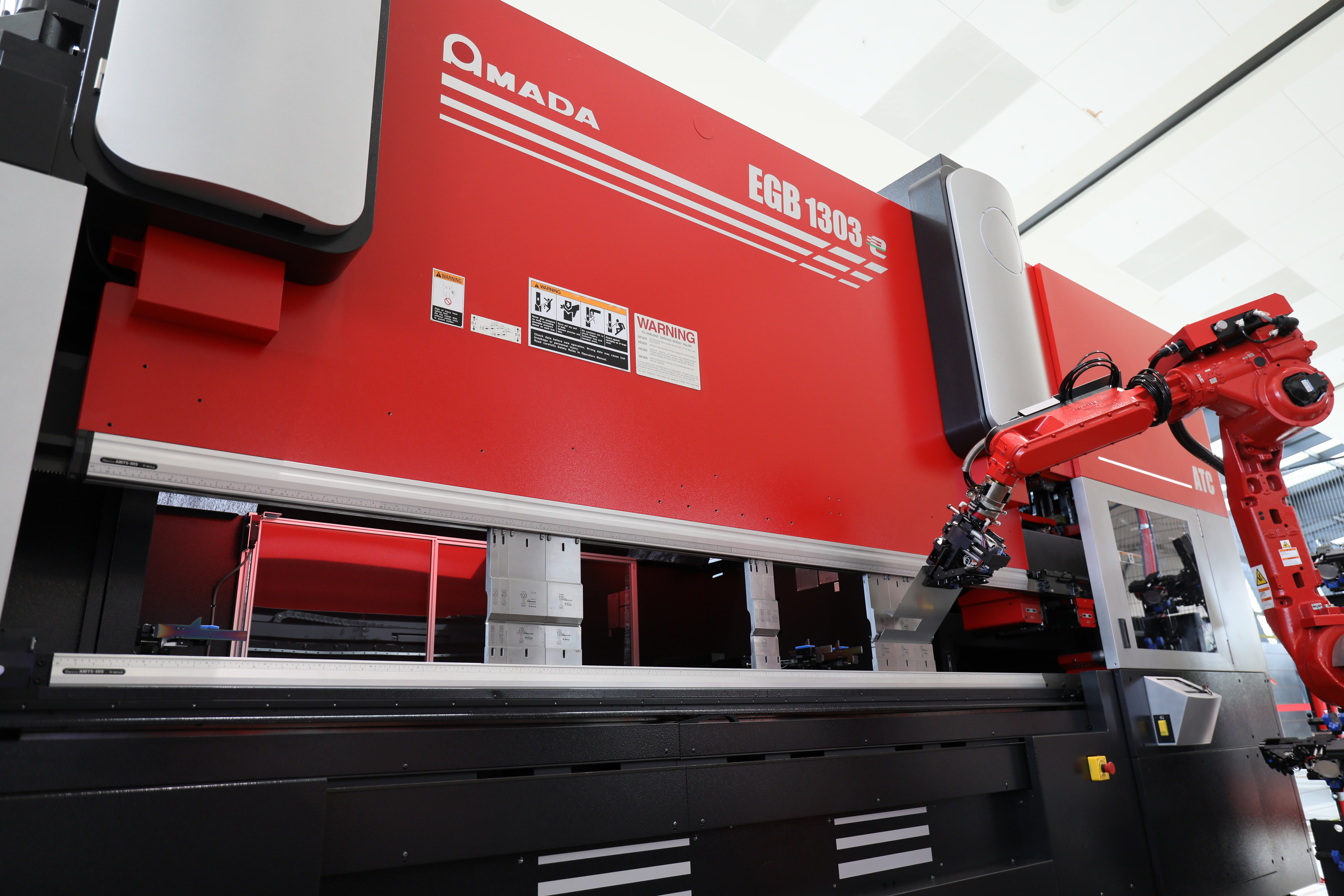

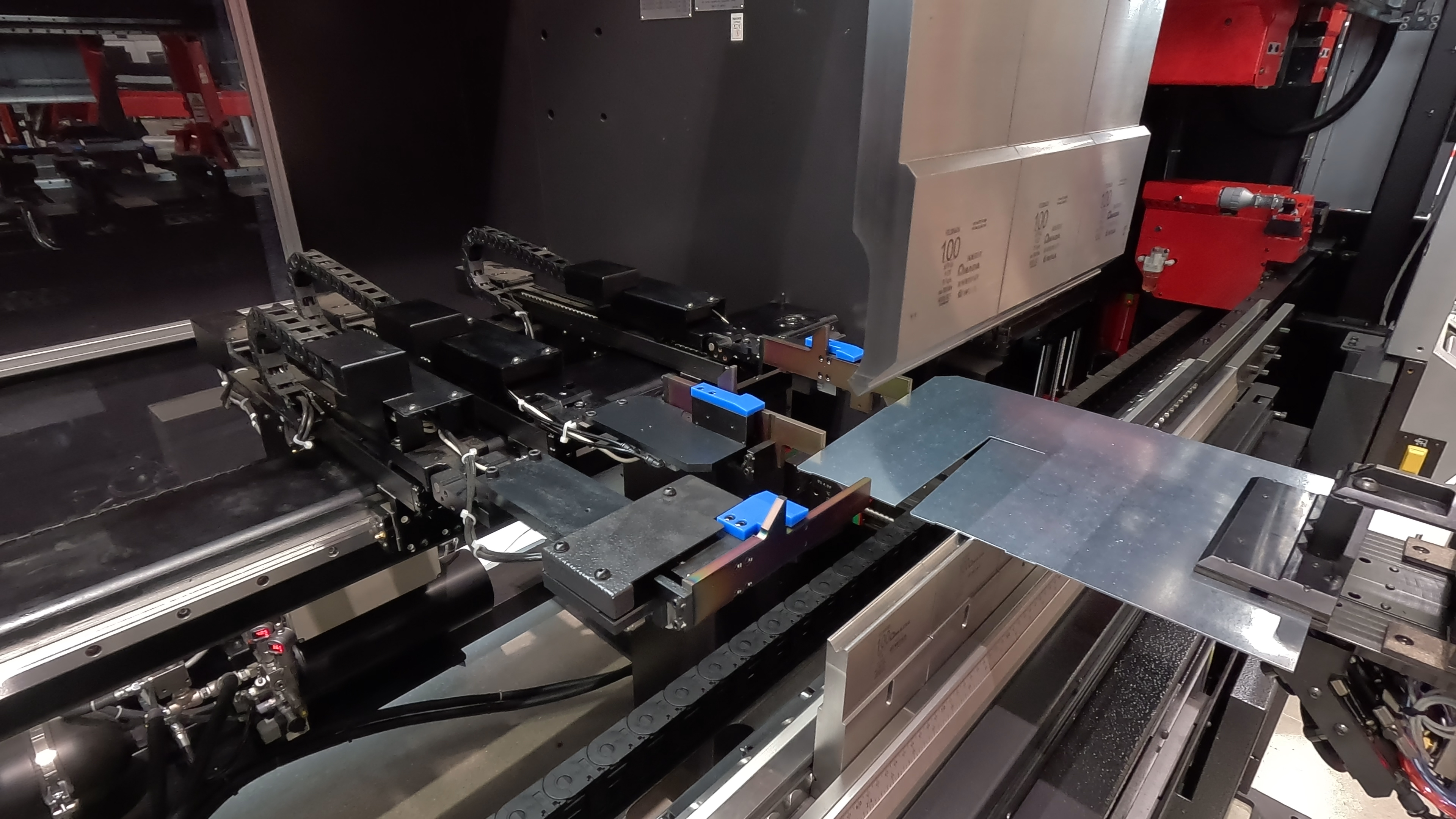

fully-integrated Electric robotic bending system

The EGB 1303 ARs is a fully-integrated robotic bending system with a 6-axis bending robot with a traveling axis, automatic gripper changer, and automatic tool changer (ATC) with patented AMADA tooling. Each stage of the bending process, including tool loading, gripper exchange, and robotic bending are all performed at fast speeds to maintain high levels of unmanned machine productivity. The ATC is equipped with four tool manipulators that quickly and precisely position punches and dies along the length of the press brake to eliminate costly delays associated with manual tool changes.

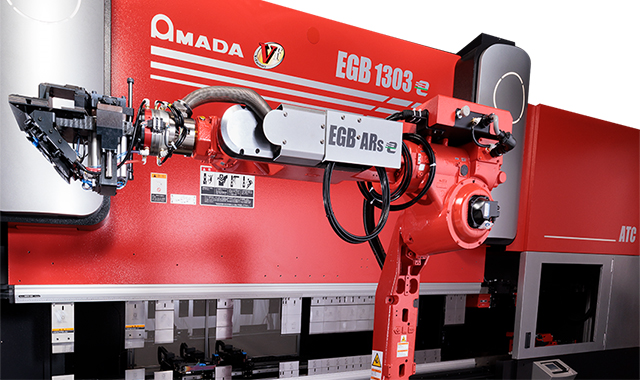

Versatile Bending Robot

To maximize bending flexibility, the EGB ARs is equipped with a 6-axis robot

with a traveling axis. Mounted on a rail in front of the EGB ATC press brake, this

fully-integrated robot can traverse along the length of the press brake to facilitate

multi-stage bending. The enhanced motion capabilities allow this robot to easily

perform acute and obtuse bends. Also, the newly developed robot controller

improves cycle times and has a reduced footprint to make the machine more

compact.

In adherence to the primary section of AMADA's Basic Policy on Sustainability, we are committed to treating people and the global environment with respect. We achieve this goal by reducing CO2 emissions, promoting the reduction and reuse of waste, and protecting the global environment, including biodiversity in all processes. We also provide environmentally-friendly products and services through our business activities. https://www.amada.co.jp/en/sustainability

Intelligent AMNC 4ie control

An intelligent AMNC 4ie control allows voice commands to request, change, and verify bend information while the operator is on the moveall as an automatic foot pedal slides to the next

bending position to ensure continuous operation.

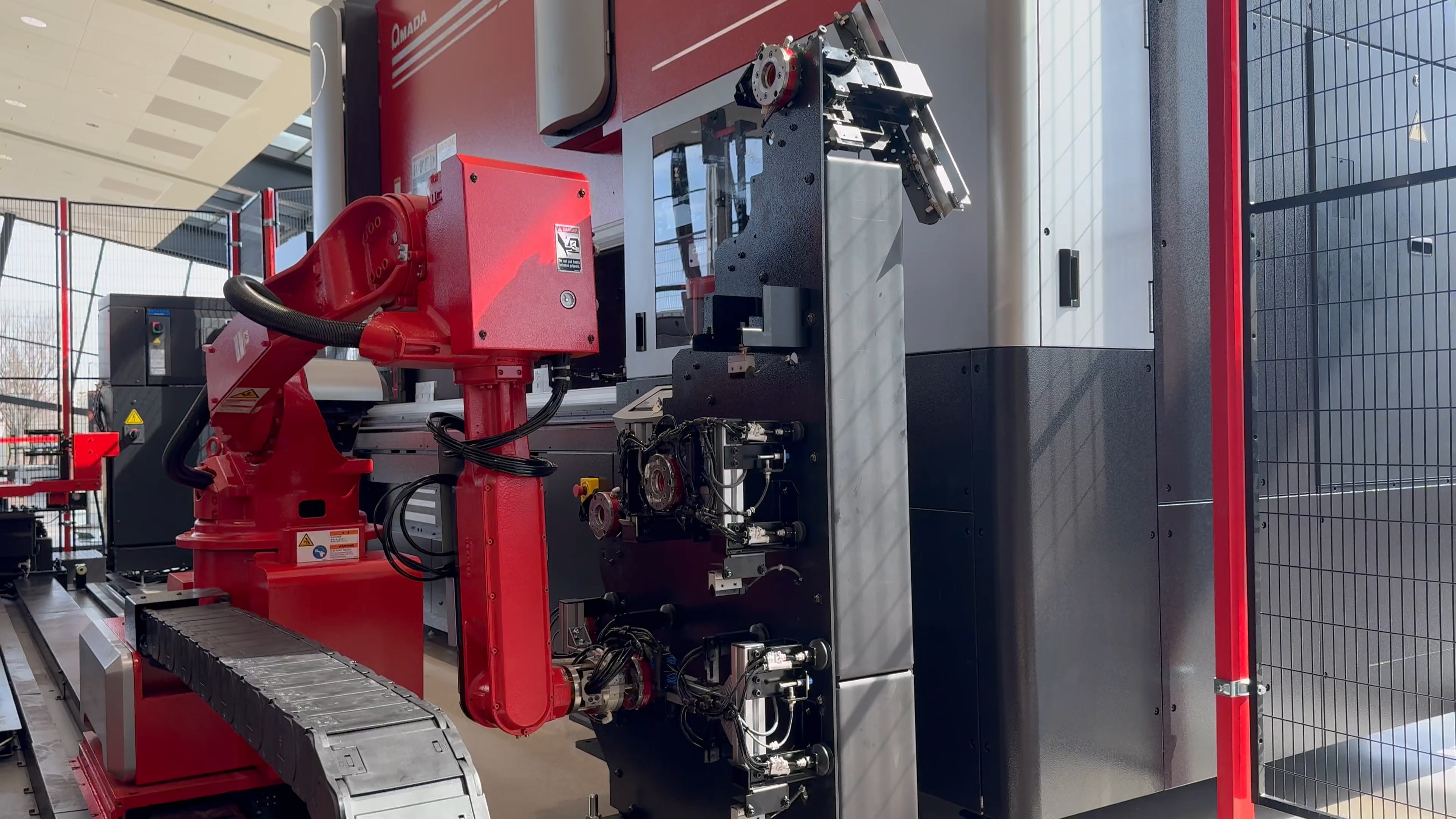

AMADA's Patented Automtic Tool Changer(ATC)

By integrating a bending robot with the precision of AMADA's EGB ATCe press

brake and patented Automatic Tool Changer (ATC), fabricators can automatically

bend a variety of parts with maximum accuracy.

AMADA's ATC ensures that tools are loaded quickly and precisely. Four tool

manipulators quickly load tooling from 18 punch stockers and 25 die stockers. Each

stocker can hold 800mm of tooling. The ATC was engineered to eliminate costly

delays associated with manual tool changes.

AMTS Tooling

AMADA’s Modular Tooling System or AMTS is designed to account for the motion

during loading and unloading and accurate punch tip alignment. The design of AMTS

tooling is an important factor as to why the ATC loads the most complex tool

setups in minutes and decrease setup times for longer parts.

Automatic Gripper Changer

The Automatic Gripper Changer will exchange the gripper according to

the workpiece to ensure efficient and stable processing. This machine is

equipped with various types of grippers to accommodate a wide variety of

parts shapes and sizes.

Two Backgauge System w/ Side gauge

A two backgauge system with a side gauge ensures stable positioning of asymmetrical workpieces and simplifies positioning. The side gauge corrects lateral misalignments and stabilizes lateral positioning.

BI-S II Angle Sensor

To further boost productivity, Bi-S II automatically measeure and corrects angles up to 85% faster than Bi-S Technology.

In adherence to the primary section of AMADA's Basic Policy on Sustainability, we are committed to treating people and the global environment with respect. We achieve this goal by reducing CO2 emissions, promoting the reduction and reuse of waste, and protecting the global environment, including biodiversity in all processes. We also provide environmentally-friendly products and services through our business activities. https://www.amada.co.jp/en/sustainability

Features

- 130-ton capacity servo/electric drive system

- AMNC 4ie Control with vertical multi-touch display

- ATC stores 112.8' of patented AMADA tooling and is equipped with four tool loaders

- Multi-axis robot performs consistent unmanned bending operations

- Two backgauge system w/ side gauge ensures high-precision bending operations

- Offline programming software generates all articulation code for the robot and press brake

- Bi-S II angle sensor ensures consistent bend angles

- 9 gripper station allows robot to move seamlessly from small parts to larger panels